Researchers at Drexel University are experimenting with infusing concrete with living organisms to extend the lifespan of building materials. And while the new approach is based on cutting-edge technology, its underlying engineering strategy comes from inside the human body.

Since concrete has properties second only to water, most consumed material On Earth, this is a particularly troubling statistic considering the huge carbon footprint of manufacturing processes. While many promising and environmentally friendly updates to millennia-old structural materials are already underway, another means of reducing concrete’s environmental impact is to extend its lifespan. Depending on the surrounding environment, concrete can weaken and begin to break down as early as 50 years after hardening. Slowing down this degradation using innate real-time repair mechanisms could provide a reliable way to get more out of the material.

[Related: Dirty diapers could be recycled into cheap, sturdy concrete.]

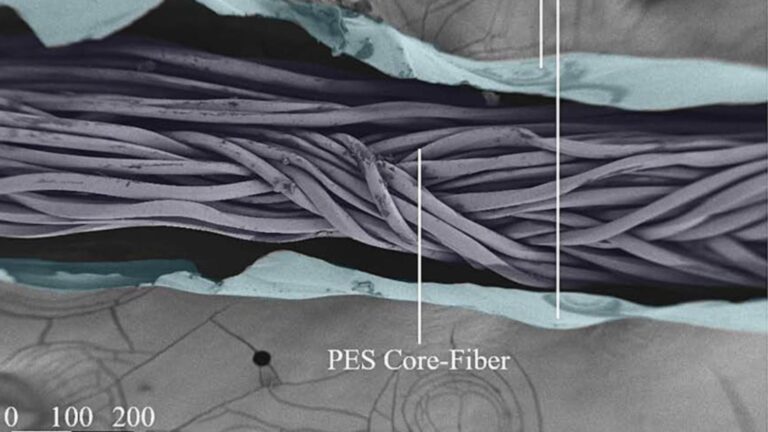

As detailed in a recently published new paper, construction and building materialsA team of engineering researchers at Drexel University has developed a new polymer “biofiber” coated with a bacteria-infused hydrogel. All within a 0.5mm thick damage-reactive casing. The biofibers are then placed in layers in a lattice pattern when pouring the concrete, creating a reinforcing additive in the same way that builders have used straw and horsehair to strengthen bricks for thousands of years. functions as Of course, there’s only so much you can do with these reinforcements, but when your team’s biofibre starts to decline, that’s when they really shine.

“In our skin and tissues, [repairs] “It heals naturally through a multilayered fibrous structure that is injected with blood, a self-healing fluid,” said Amir Farnham, associate professor of engineering at Drexel University and co-lead of the study. University profile on December 8th. “These biofibers mimic this concept, using stone-making bacteria to react to damage and create a living, self-healing concrete.”

Inside each biofiber, Ricinibacillus sphaericus in dormant endospore form. Commonly present in soil, this bacterium undergoes a process known as microbial precipitation of calcium carbonate. Basically, it produces a rock-like substance when it consumes nutrients.

This is particularly useful if, for example, bacteria are found near newly formed cracks in certain popular building materials. When the team’s biofibers break down under stress, water from the external environment eventually finds its way into the concrete, where it comes into contact with the bacteria on the endoscope.This will activate Ricinibacillus sphaericusIt begins to be pushed towards the surface while calcium carbonate precipitation, caused by microorganisms, begins. That calcium carbonate then fills the offending crack, ostensibly hardening into a cement scab, much like when dried blood covers and protects a cut. In a recent test, the concrete “healed” itself within two days.

Researchers need to better understand and control healing times for materials embedded with biofibers, but self-healing materials may one day help reduce the need for additional concrete, which is costly to climate change. .