KTH Royal Institute of Technology

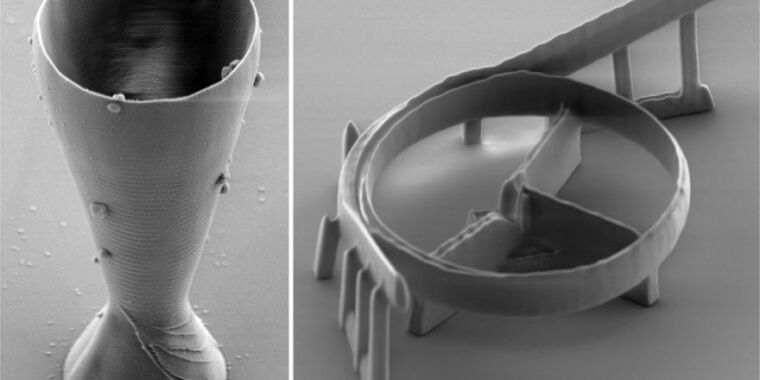

A team of Swedish scientists has developed a new 3D printing technology. quartz glass Streamline complex, energy-intensive processes. As a proof of concept, they 3D printed the world’s smallest wine glass (made of real glass) with a rim smaller than the width of a human hair and an optical cavity for a fiber optic communication system. 3D printed fused silica parts. They described their new method as follows. recent papers Published in Nature Communications.

“The backbone of the Internet is based on glass fiber optics.” Co-author Kristin Gilfason said: PhD from KTH Royal Institute of Technology, Stockholm. “These systems require all sorts of filters and couplers, which our technology now allows him to 3D print, which opens up a lot of new possibilities. ”

According to the authors, silica glass (i.e., amorphous silicon dioxide) remains one of the materials that remains a challenge for 3D printing, especially at the microscale, but also for stereolithography, direct ink writing, digital light processing, etc. , several methods have attempted to address that challenge. Even with them, we can only achieve feature sizes of the order of tens of μm, except for 1 μm. 2021 survey reported nanoscale resolution.

But they are all sol-gel A process involving various organic mixtures loaded with silica nanoparticles. As a result, the final printed structure will be a composite material containing many organic materials, thus exhibiting the most desirable properties of silica glass (i.e. thermal and chemical stability, hardness, optical transparency over a wide range of wavelengths). Missing. An additional sintering step at elevated temperatures of approximately 1200°C (2192°F) for several hours is required to remove organic residues and achieve these properties. Only substrate materials that can withstand such high temperatures can be used, so the energy-intensive additional step severely limits potential applications. Some approaches also require 3D-printed structures to be assembled into their final shape, which is difficult at the micrometer scale.

In developing alternatives to 3D printing fused silica, Gylfason other.Became hydrogen silsesquioxane (HSQ), a silica-like inorganic material that can be patterned by electron beams, ion beams, and UV light of specific wavelengths. One of the major advantages is that their method does not rely on organic compounds acting as photoinitiators or binders that remain on the substrate, like stereolithography and direct ink writing. Instead, their method relies on direct cross-linking of inorganic HSQ.

This process has three main steps. First, HSQ dissolved in an organic solvent is drop-cast onto the substrate. Once the HSQ is dry, trace the desired 3D shape using a focused sub-picosecond laser beam. Finally, unexposed HSQ is dissolved by a simple application of potassium hydroxide solution. Raman spectroscopy of the printed microstructure showed all the features expected of silica glass.

However, trace amounts of hydrogen and carbon also remained. For applications requiring a purer silica glass, the structure can be annealed at 900 degrees Celsius (1,652 °F) to remove residual organics. Although this is an approved additional step, it is done at a much lower temperature than the normal additional sintering step. The spectrum of the structure then matched that of a commercial fused silica glass substrate. Annealing 3D-printed microstructures can lead to shrinkage and distortion, but the authors found that using stereolithography and direct ink writing methods, the maximum shrinkage of silica glass structures is about 6 percent, whereas the maximum shrinkage is about 6 percent. I found it to be between 16 and 56 percent for the glass objects created. .

In addition to a small proof-of-concept wineglass and optical cavity, the authors also printed the KTH logo, a cantilever, a small version of the conical spiral, and even the tip of a fused silica optical fiber. They believe their method can also be used to manufacture customized lenses for medical devices and microrobots. Coating 3D-printed microstructures with nanodiamonds or iron nanoparticles has the potential to further tune the properties of hybrid quantum photonics integration or to magnetically remove structural motion control, respectively.

“Concerns when integrating 3D printing methods are typically different for each application.” Co-author Pohan Huang said:, a graduate student at KTH. “Although optimization of our method is still needed for different applications, we believe that our method provides important and necessary breakthroughs for using 3D glass printing in real-life scenarios.” believe.”

DOI: Nature Communications, 2023. 10.1038/s41467-023-38996-3 (About DOIs).