Toriyama Co., Ltd.’s expert butchers have been producing the finest Wagyu beef for 20 years. Toriyama is one of the few producers that control every aspect of beef production from start to finish. “Our philosophy is to produce our own beef,” says Shota Odabashi, Toriyama’s expert butcher. “And we make sure every part of the cow tastes delicious.”

Toriyama’s farm currently has 1,400 Japanese Black cattle. What makes Wagyu different from other beef breeds is the long-term care of the cattle. It takes three years for a cow to be slaughtered after it is born. Every day, Wagyu calves are born on Toriyama’s farm. After one week, they are moved to the barn where the nursery department provides them with temperature-controlled feed. When the calves reach three months of age, they are moved back to the barn and given two types of nutrients: rice for energy and miso paste to supplement protein and minerals. Each cow is carefully cared for until it is shipped off for slaughter.

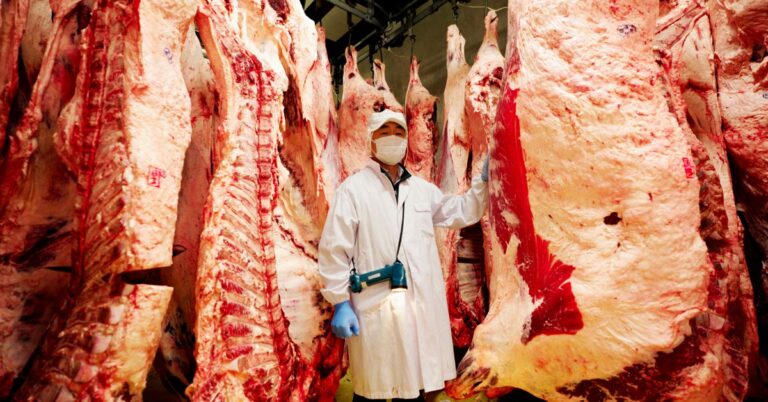

The cows are slaughtered, cleaned, and then sent to a processing facility. The first step in the process is to separate the carcass into the front and back. The front is cut into the shoulder and chunks, while the back is cut into the loin, belly, and shoulder eye. Once these five cuts are removed, the meat is separated into various cuts. For example, the most expensive cut, the fillet, comes from the back. All of Toriyama’s cuts are prepared by butchers who are Meister-certified (professional certification in meat processing). “Seeing my colleagues deboning and cutting meat with such craftsmanship, I wanted to become a skilled craftsman like them,” says Odabashi, who became a Meister in eight years.

Watch the latest episode vendor Learn how Toriyama produces world-class beef products.