3D printing is one of the most promising technologies of this century. for many years now Its great potential is being practiced in fields such as biomedicine.. But this is not a special case. Architecture is also taking advantage of 3D printingis even considered the best option for potentially urbanizing the surface of Mars in the future.

3D printing is no longer new as it has already become a fixed concept. But engineers and researchers around the world are literally trying to add another dimension to it, and some projects have done just that. 3D printing gives birth to 4D printing. But what does this mean?

4D printing, the key lies in the material

4D printing aims to create intelligent objects by 3D printing, but provides them with an additional variable: time. For that, Printed materials that can adapt and interact with the environment. In other words, take advantage of pre-patterned materials that can be placed and changed in shape autonomously without human intervention.

The key to 4D printing is therefore sometimes in the specific materials rather than in the already well-known 3D printer-based process. Can self-build and repair. 4D printing opens up a whole new world of possibilities in medicine, civil engineering and construction. It enables the creation of devices with the ability to react in advance of changes in temperature, pressure and humidity and adjust accordingly.

- medicine and surgery

- clothes and shoes

- Aviation and Automotive

- construction

- architecture

- Transportation and Logistics

- computer industry

Smart fabrics that can automatically adjust temperature, etc.

For example, Georgia Tech has successfully developed a flower-like structure featuring 3D-printed petals that can adjust their shape in response to changes in temperature. For that to happen, scientists looked to: tensegrityIt is a construction principle based on the use of independent components in compression within a fully cabled net of continuous tension. These materials featured pre-engineered thermal structures and reacted with water at 65 °C. Despite the compression, we were finally able to achieve the desired shape.

Based on the results obtained during the course of the project, and thanks to the lightweight and durable nature of these materials, the system will transport disassembled or scaled-down structures into space, where they will assume their final shape. may allow it to be obtained.

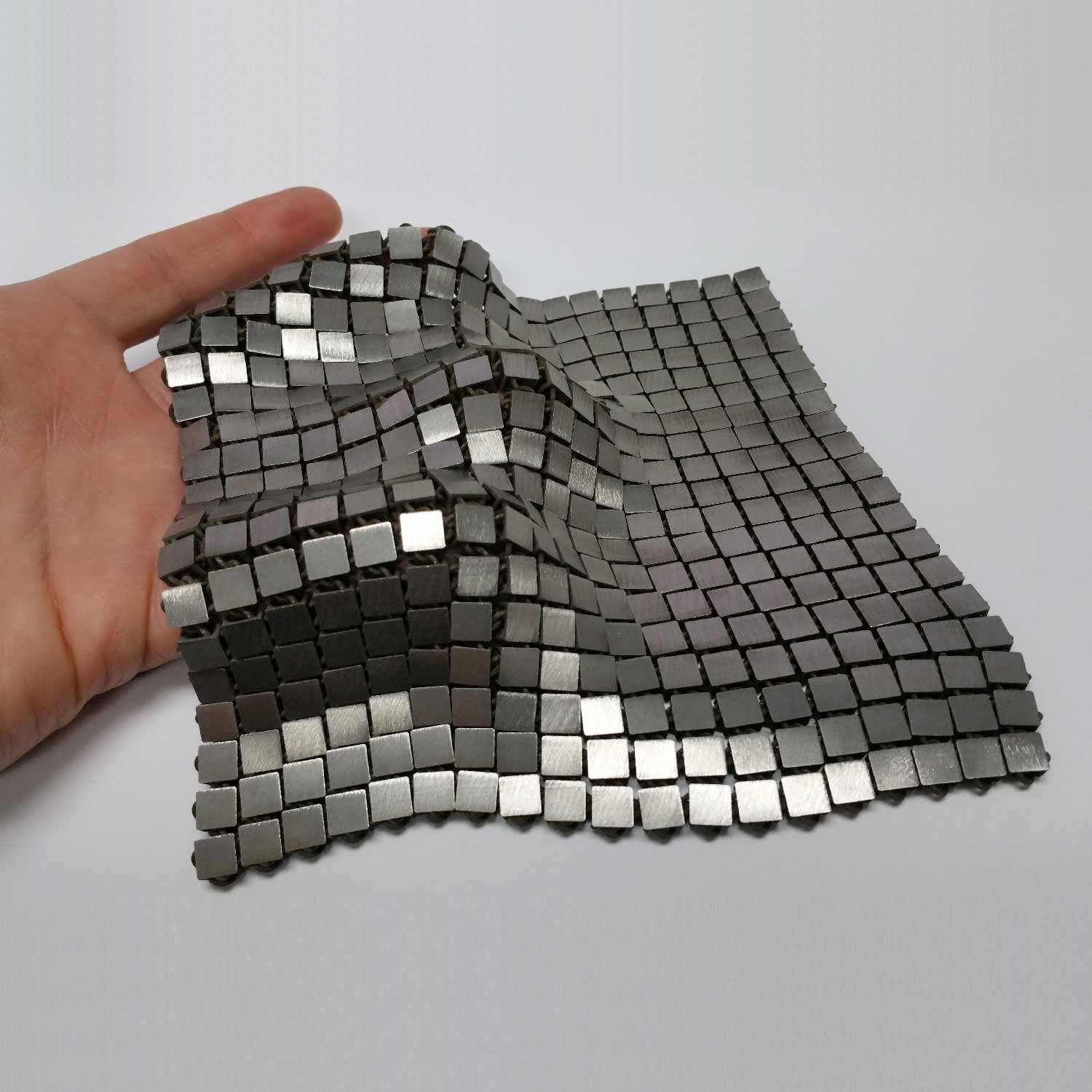

But you don’t have to travel very far to encounter the most encouraging news on the subject. Spanish engineer Raul Pulido Casillas used 4D printing to develop smart fabrics for NASA. This wire mesh-like structure consists of attached silver strips and has a built-in temperature control program. In other words, not only the shape but also the functionality of the material is printed.

It can reflect heat on the outside and retain it on the inside, making it an ideal material for making space suits and coating spacecraft.

With progress like this, the conquest of space seems ever closer. But while my feet are still on the ground, let me tell you this. Biomedicine is another field that will benefit greatly from 4D printing.. Vascular stents and other devices Features tailored to each patient’s needs, such as expanding in response to body temperature in the face of cardiovascular problems, are already under development.

All this and much more. The novel adaptability properties of these materials offer solutions for developing fabrics that change color in response to light, surfaces that can change their permeability depending on environmental humidity, and materials with the ability to increase resistance to external forces. There is likely to be.

Fuentes: abc.es, Zatakaciencia, information library, La Vanguardia, RT.com

Imagen: NASA/JPL-Caltech